Polyethylene Terephthalate (PET) and Its Applications

Polyethylene terephthalate (PET) is a thermoplastic polyester resin with the chemical formula (C10H8O4)n. Such resins can be classified based on their viscosity. PET with low viscosity has a viscosity of less than 0.75, whereas high-viscosity types have a viscosity of 0.9 or higher. This polymer is practically unbreakable, colorless, lightweight, and falls into the category of transparent polymers.

PET exhibits high strength, especially in beverage bottles, making it suitable for the production of portable and sports bottles. Its transparency allows the contents inside the containers to remain visible, which is a crucial aspect in the food industry.

The weight of PET bottles is very low and has consistently decreased in recent years, typically ranging from 20 to 30 grams today. One of the important properties that has made this compound suitable for various applications is its high compatibility with other thermoplastic polymers such as polyethylene, polypropylene, polycarbonates, polystyrene, ethyl vinyl acetate, etc.

Properties:

- Property

- Value

- Chemical Formula

- C10H8O4)n

- Melting Point

- 260 degrees Celsius

- Normal Mold Temperature

- 74 to 91 degrees Celsius

- Heat Deflection Temperature

- 70 degrees Celsius

- Tensile Strength

- 152 megapascals

- Flexural Strength

- 221 megapascals

- Specific Weight

- 1.1

- Density

- 1.37 grams per cubic centimeter

Production Method of Polyethylene Terephthalate

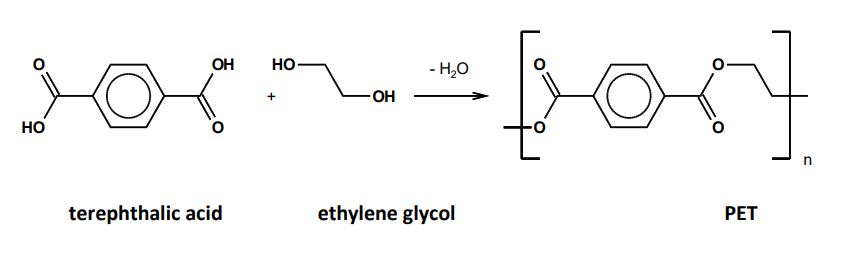

Commercially, polyethylene terephthalate resins are produced from ethylene glycol and either dimethyl terephthalate (DMT) or terephthalic acid (TPA). Both DMT and TPA are solids, with DMT melting at 140 degrees Celsius while TPA sublimates.

In both processes, an intermediate monomer, bis-2-hydroxyethyl terephthalate (BHET), and also methanol (in the DMT process) or water (in the TPA process) are produced initially. Then the BHET monomer is polymerized under low pressure and in the presence of a catalyst and heat to produce PET.

The primary reaction for the TPA process is as follows:

Reaction:

Both reactions have the capability to produce products of high and low viscosity. The viscosity of the final product is determined by the operational conditions of polymerization, including pressure (vacuum level), temperature, residence time, and flow turbulence (mechanical design).

Production Process from Dimethyl Terephthalate:

Both batch and continuous operations can be used for production from DMT. There are three fundamental differences between continuous and batch operations:

- A column reactor replaces the kettle reactor for esterification.

- Reactors without agitators are required for continuous operations.

- Different additives and catalysts are needed to achieve desired properties (such as molecular weight and molecular weight distribution).

Applications of Polyethylene Terephthalate

Low-viscosity resins, sometimes referred to as PET staple (textile grade), find applications in various products such as textile fibers, bottles, and photographic films. High-viscosity resins, sometimes called industrial or high-denier, are used in the production of ropes, safety belts, etc.

This material is widely used in the production of synthetic or artificial fibers (such as polyester fibers), which constitute the largest portion of the synthetic fiber industry. PET is also extensively used in food packaging such as beverage bottles and frozen foods that can be heated in a microwave.

PET Bottle Production

These bottles are produced in two main stages. Initially, granules are melted at temperatures above 280 degrees Celsius and converted into preforms, which are small and very easy to transport. Shortly before the filling process, preforms are heated to 120 degrees Celsius and blown into their final bottle shape. A one-step process can also be performed, where PET is directly sent from the injection stage to the blowing stage. After cooling, the bottles are filled with the beverage.

The stretch blow molding process causes polyethylene terephthalate to crystallize relatively, which results in reduced transparency, improved bottle stability, and increased resistance to oxygen and carbon dioxide.

Textiles

Polyethylene terephthalate has numerous applications in textiles. Polyester fibers are strong and flexible, with less wrinkling and shrinkage compared to cotton. PET is highly transparent without crystals, while the fully crystalline type is completely opaque and used for microwave containers and trays. Due to its excellent anti-static properties, this material is also used in the electrical and electronic industries for insulation materials.

3D Printing Applications

As this material is a strong and flexible polymer, it is very suitable for 3D printing. Other materials such as Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA) are also used for 3D printing, but PET has the advantage of producing less odor.

Recycling

Recycled PET can be used to produce some fabrics, sleeping bags, and insulating materials. In some cases, it can also be used for bottle-to-bottle recycling, but this requires the use of a clean recycling process and approval from medical and food authorities.

Advantages of Polyethylene Terephthalate

Many different industries can benefit from the numerous advantages of this product. When it comes to storage, transportation, pollution, and lifespan, PET is often a clear choice.

- Crystal-clear appearance: PET bottles are as transparent as glass bottles.

- Unbreakable: PET bottles are practically indestructible, making them a suitable option for storage and transportation.

- High impermeability: Products made from PET are impermeable to water, carbon dioxide, and oxygen. These properties help protect and preserve the integrity of any product.

- Lightweight: PET bottles are very lightweight, saving approximately 30% in transportation costs compared to glass.

- Excellent flexibility: Polyethylene terephthalate is suitable for making containers in all shapes, sizes, colors, and designs.

- Recyclability: Ultimately, 100% of the polymer used is recyclable. In fact, this product is the most widely recycled plastic in the world. According to a report by NAPCOR in 2013, approximately 5764 million PET bottles and plastics were available for recycling. Almost 85% of these bottles are used for beverages and food, equivalent to 4899 million pounds.

- Excellent electrical insulation: PET has excellent chemical resistance to alcohols, aliphatic hydrocarbons, oil, grease, and dilute acids.

- Moderate chemical resistance: PET has moderate resistance to thinners, aromatics, and halogenated hydrocarbons.

Kala Sanat Alborz is with you every step of the way in your business journey.

Kala Sanat Alborz provides the best and best-selling chemical materials from the best suppliers in the world with the ability to customize orders for every customer with 25 years of experience (product list). What you need, ask us.

Kala Sanat Alborz helps you buy and sell polyethylene terephthalate (PET) with just one call to our experts.

At Kala Sanat Alborz, we have provided you with the fastest and most secure way to buy and sell chemical materials at the global standard level. Take action now with confidence to buy and sell chemical materials in the market.

Write your opinion